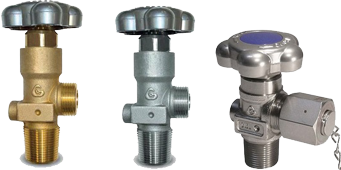

Stainless steel specialty gas cylinder valve connections

Cylinder valves are made in Europe and approved for use by Air Liquide and Linde gas. All valves are supplied with a two year warranty.

Stock includes:

Cylinder Valve Connection to AS2473.2 Type 32

(For use with ammonia and sulphur dioxide)

Cylinder Valve Connection to AS2473.2 Type 40

(For use with cyanogen, ethylene oxide, hydrogen cyanide and vinyl chloride)

Cylinder valve connection to AS2473.2 Type 43

(For use with hydrogen bromide, hydrogen chloride, hydrogen sulphide and methyl mercaptan)

Cylinder valve connection to AS2473.2 Type 44

(For use with non-flammable toxic mixtures)

Cylinder valve connection to AS2473.2 Type 45

(For use with flammable toxic mixtures)

DIASPEC S200 Series – Stainless steel high pressure diaphragm seal valve

Features

- Low operating torque guaranteed due to soft sealing

- Valve seat secured against extrusion

- Extreme leak tightness achieved by diaphragm sealing

- High Flow Capacity to allow fast filling and vacuum

- Clean room assembly

- 100% helium leak test

- All markings on the valve neck protected against damage

- All inlet and outlet standards available

Technical Data

| Maximum Service Pressure | 230 Bar |

| Pressure Test | 276 Bar |

| Temperature Storage | -40°C to +65°C |

| Minimum Life Cycle | 2,000 |

| Helium leak Rate | |

| Internal | 10E-7 atm cc/s |

| External | 10E-7 atm cc/s |

| Safety | 10E-8 atm cc/s |

| Flow coefficient CV | 0.4 |

| Diaphragm | AISI 316 L, Hastelloy or Stainless Steel |

| Seat orifice dimension | 4mm |

Material Components

| Body Material: | AISI 316 L |

| Diaphragm: | Hastelloy Stainless Steel |

| Spindle: | AISI 316 L |

| Seat Disc: | PA6,6 PCTFE |

| Bursting disc: | NickelAISI 316 L |

DIASPEC TD S200 Series – Stainless steel high pressure tied diaphragm seal valve for high purity gases

Features

- Low operating torque guaranteed thanks to the teflon coated upper stem

- Valve seat pad secured against extrusion

- Extreme leak tightness achieved by back-up welded diaphragm sealing

- High Flow Capacity to allow fast filling and vacuum purging

- Clean room assembly

- 100% helium leak test

- All markings on the valve neck protected against damage

- All inlets and outlets standards available

- Easy purging process allowed by reduced dead spaces and gas wetted volumes

- Lock of threads and springs in a wet area ensures minimum particulate generation

- Gas doesn’t contact the valve operating mechanism

Technical Data

| Maximum Service Pressure | 230 Bar |

| Pressure Test | 276 Bar |

| Temperature – Operating | -40°C to +65°C |

| Temperature – Storage | -40°C to +65°C |

| Minimum Life Cycle | 2,000 |

| Helium leak Rate | |

| Internal | 10E-8atm cc/s |

| External | 10E-8atm cc/s |

| Safety | 10E-8 atm cc/s |

| Flow coefficient CV | 0.4 |

Material Components

| Body Material: | AISI 316 L |

| Diaphragm: | HastelloyStainless Steel |

| Spindle: | AISI 430F AISI 316 L |

| Seat Disc: | PCTFE |

| Bursting disc: | Nickel – AISI 316L AISI 316 L |